컨텐츠

Product

OLED Cluster

Product

OLED Cluster

OLED Equipment

Cluster Type

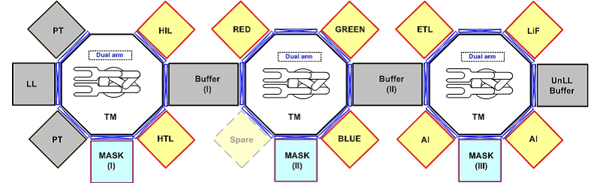

Centered on the TM (Transfer Module), it places each PM (Process Module, process chamber - chamber for functional films such as electron layer, organic matter layer, etc.) to constitute distribution by a vacuum robot.

- Core Technology

- Substrate transfer distribution technology between TM ↔ PM depending on the order of evaporation process

- Development of plate deflection prevention technology and Auto Feeding System (continuous evaporation possible for an extended period of time)

- Formation of precise evaporation patterns and Auto Aligner technology

- Development of Plasma Treatment Technology

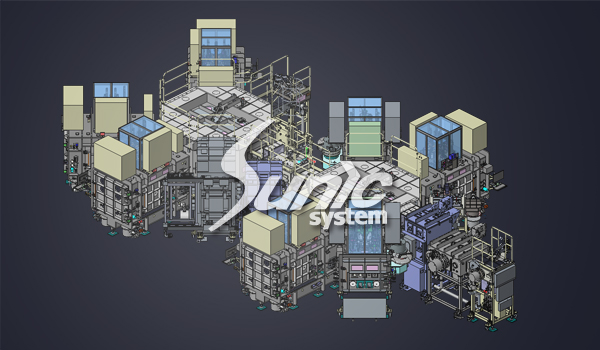

- Large-Sized Cluster Type Evaporation Equipment SystemSUNICEL Plus 1850

- For 6GH 925 * 1500 panel equipment system

- For high-resolution mobile product

- For smartphone and flexible display

- Primary clients: AMOLED panel manufacturers

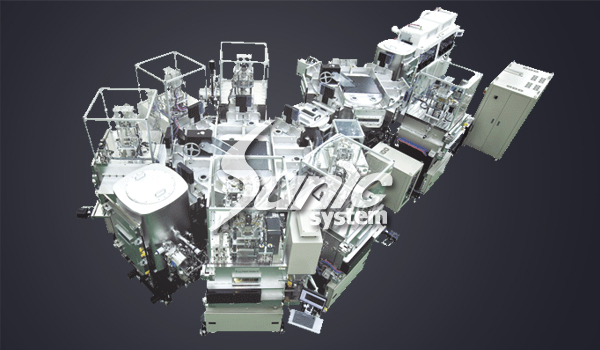

- Medium-Sized Cluster Type Evaporation Equipment SystemSUNICEL Plus 700

- For 45GH 730 * 470 panel equipment system

- For AMOLED panel pilot production and development

- Primary clients: AMOLED panel manufacturers

- Medium-Sized Cluster Type Evaporation Equipment SystemSUNICEL Plus 400

- For 2GH 370 * 470 panel equipment system

- For AMOLED panel pilot production and development

- For mass production of PMOLED panels

- Primary clients: AMOLED and PMOLED panel manufacturers

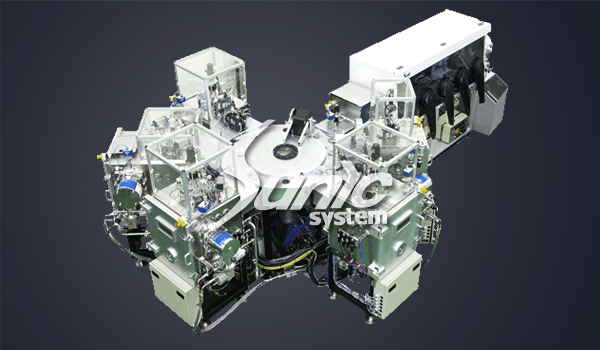

- Small-Sized Cluster Type Evaporation Equipment SystemSUNICEL Plus 200

- For 1GH 200 * 200 material evaluation and QC

- For material development and verification

- For device product development and research

- Primary clients: AMOLED panel manufacturers, domestic and international OLED materials